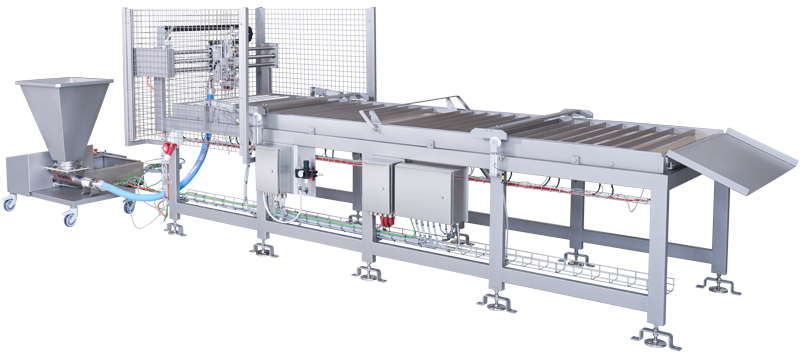

Roaster tunnel

Roasting becomes fully automatic when you use a Roaster tunnel. It frees up your staff for other tasks while the food items are roasted golden brown. The roaster tunnel automatically flips the products and can produce over 1000 meatballs per hour. The exact number depends on the thickness, size and color of the meatballs. Stepless adjustment of the roasting time ensures that all meatballs turn out absolutely perfect.

Once roasted, the processed products are conveyed to the drip tray, where excess oil drips off, then they are led out of the roaster tunnel.

The roaster tunnel from JOM A/S speeds up roasting

Technical specifications

Item No: FS 5000

Dimensions, machine: 4220 x 1600 x 1450 mm (L x H x W)

Dimensions roasting pan: 3520 x 1000 x 20 mm (stainless steel)

Dimensions wall mounted electrical cabinet: 1200 x 1000 x 300 mm

Dimensions, container: 1 x 100 litres

Roasting capacity up to: 140 kg per hour

Number of units: 1500 – 2000 pcs/hour

Power Supply: 3 x 400V + PE, 65 kW 95 A

Compressed Air Supply: 400 litres/min. 8 bar

Dosing valves: 1 piece

Dosing pumps : 1 piece

Standard molds: D70, 12 pcs

Technical specifications

Item No: FS 7000

Dimensions, machine: 5800 x 1600 x 1700 mm (L x H x W)

Dimensions roasting pan: 5100 x 1250 x 20 mm (stainless steel)

Dimensions wall mounted electrical cabinet: 1200 x 1000 x 300 mm

Dimensions, container: 2 x 100 litres

Roasting capacity up to: 280 kg per hour

Number of units: ca. 3500 – 4000 pcs/hour

Power Supply: 3 x 400V + PE, 130 kW 190 A

Compressed Air Supply: 600 litres/min. 8 bar.

Dosing valves: 2 pcs

Dosing pumps: 2 pcs

Standard molds: D70, 15 pcs

Product highlights

- Built in stainless steel

- Automatic dosing of the product on the roasting plate

- 100 kg product container with stirrer

- Touch screen for easy operation

- Automatic regulation of roasting temperature

- Stepless adjustment of roasting time

- Automatic turning station

- Automatic oil doser

- Roasting plate with removable Teflon cloth

The roaster tunnel is available in several sizes or built according to your desired specifications